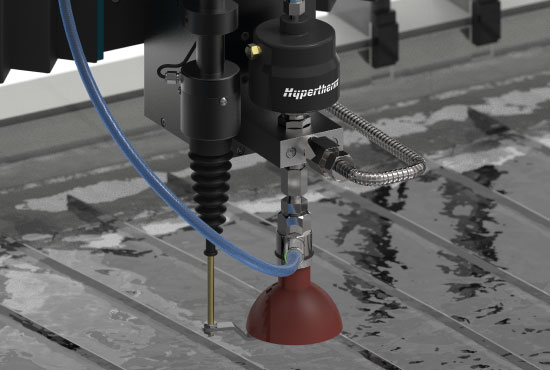

New Watertjet Cutting Service

Materials we can cut

-

Stainless

-

Mild Steel

-

Aluminium

-

Copper

-

Wood

-

Foam

-

Plastics and much more

Why use water jet cutting?

Water jet cutting delivers a range of benefits over other cutting methods and technologies, including:

-

Cold means there are no thermal influences or contamination

-

Flexible processing of vitually all materials with consistent high quality cutting

-

Intricate detail may be easily produced

-

Polished and highly reflective materials can be cut

-

Material saving production, achieved by a reduced cutting width and nesting of several parts on a single sheet.

-

Maximum degree of material utilisation thanks to the smallest of part seperationdistances.

-

Tension-free processed parts, owing to minimal cutting force.

-

Environmentally friendly and clean production without poisonous gases

-

Optimisation of cutting parameters to meet individual customer needs.

-

High material savingins due to narrow bridge or ribs

Maximum sheet size we can cut is 2500mm by 1250mm

For a free quote with no obligation please attach the file using the link below in DXF file format only, along with the material and qty needed and we will come back to you as soon as possible. If you cannot send a DXF file please send in your drawing or picture, we may need to charge to convert your drawing or picture. This charge will depend on the amount of work that will be need to covert to a DXF FILE, again we will give you a free no obligation quote to do this. However we can not quote for any cutting until we have a true DXF file.